COS

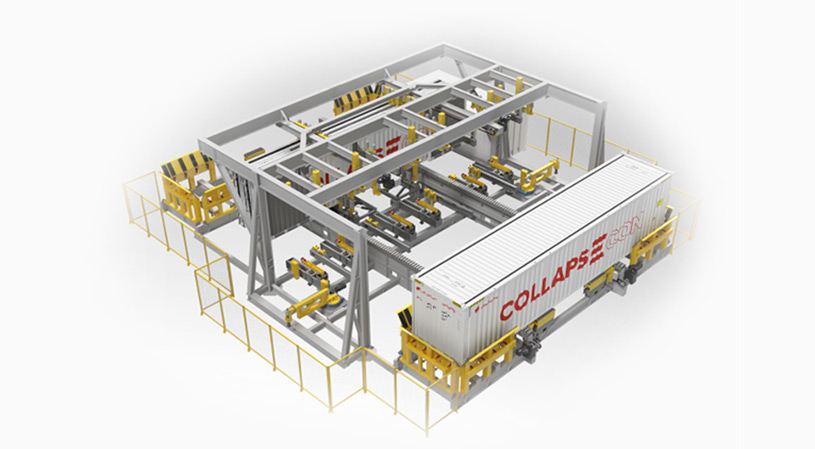

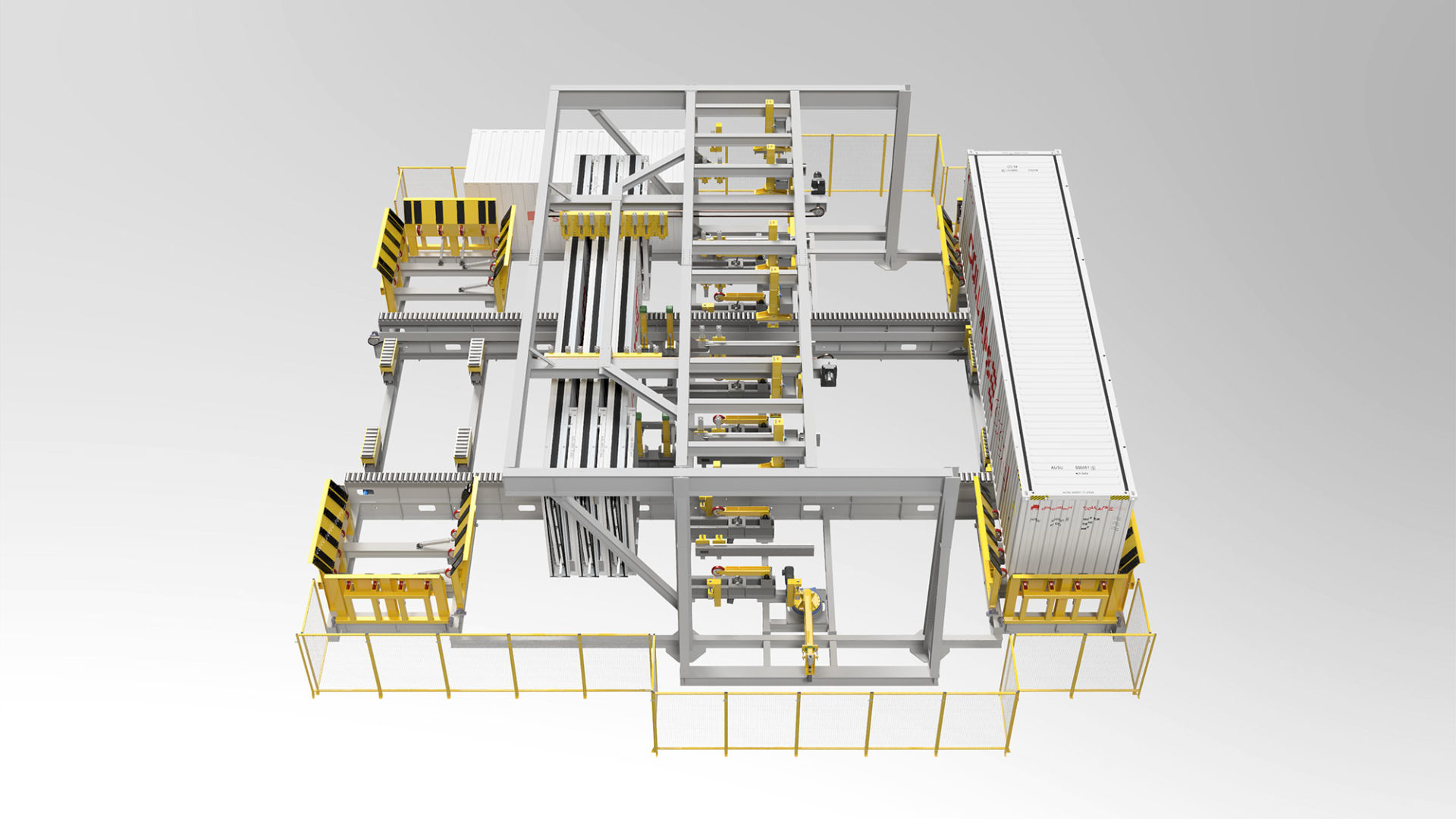

For collapsible containers to be effective and generate real impact, they need to be employed at scale. To achieve scale, the right hardware is required to collapse and combine containers with speed and safety. No ad-hoc, manual process will do. The COLLAPSECON Operating Station (COS) sets COLLAPSECON apart by being the world’s only fully automated collapsing or expanding system. Its speed and scale drives cost, productivity and environmental savings for users.

Integrating COS into the supply chain

COS is the only way to collapse or expand COLLAPESCON containers and to reap the benefits of speed and scale that they offer together. It is the blue-sky solution that replaces manual and unsafe collapsing solutions and leads the way forward to a more economical and sustainable supply chain.

With full automation and a specific partnership between the collapsing station and container, COS has the added benefit of reducing wear and tear on containers to extend working life and reducing downtime.

COS can handle 1,000+ COLLAPSECON units per week, collapsing them into 250 COLLAPSECON blocks. This means greater volumes can be repositioned back to demand ports and more cargo can be loaded for return journeys.

Fully automated

Automation introduces unprecedented economies of scale. Faster collapsing reduces empty container park and terminal footprints, while increasing throughput.

Speed

COS is designed to collapse and expand COLLAPSECON in 2 minutes, creating a COLLAPSECON Bundle that is ready to go at all times. The same applies to separating containers from their bundles.

Mobility

With complete mobility, COS is designed to be packed into four COLLAPSECON units for easy transport and re-deployment between your customers, empty parks, and terminals if required.

Safety

Housed securely in the operator’s station, the automated process is conducted and monitored safely with an array of sensors that detects operations and performs an emergency stop.

| COLLAPSECON OPERATING STATION (COS) | |

|

Physical |

|

| Dimensions |

19m x 19m x 7m

62.3 ft x 62.3 ft x 22.9 ft |

| Weight | 56,000 t |

|

Power Supply |

|

| Standard | 415v 120 A MIN |

|

Safety |

|

| Operation | Fully automated |

| Container in feed | Remotely operated from separate control room |

| Auto shut off | 12 infrared sensors ensure accurate feed/operation |

| Collapsing per container | 2 mins |

| Expanding per container | 2 mins |

| Method | Horizontal |

| Infeed/Outfeed | Reach Stacker (30t rated for combined removal) |

|

Deployable |

|

| Location Flexibility | Designed to be packed into 4 40’COLLAPSECON’s plus the control unit and be fully mobile within 24 hrs. |

Frequently Asked Questions

Why do I need a COS in addition to COLLAPSECON containers?

Future trade and the global container fleets will grow, and automation is the solution to managing container stock and wasteful empty re-positioning. Storing stacks of idle containers on a large footprint or acquiring additional land for additional volumes of empty containers is inefficient and costly. COLLAPSECON and COS working in tandem to reap the benefits of speed and scale. It is the blue-sky solution that replaces manual and unsafe collapsing solutions.

Why is the speed of the COS so important?

The shipping and logistics industries are big. With millions of containers and hundreds of millions of container movements every year, scale requires speed. Because each operation takes less than 2 minutes, COLLAPSECON offers the opportunity to implement collapsible containers on a global level, including the major trade routes of Asia/Europe, Asia/WC North America, Asia EC North America and the Transatlantic. These economies of scale optimise costs, increase productivity and create significant environmental benefits.

How many COS will I need, and where should I position them?

Every business is different, as are the needs of your customers. We work with you to understand and identify the optimal number of COS required to operate your COLLAPSECON fleet. Whether located at a customer’s premises, a transport depot, a railhead/ramp, an inland barge terminal, an empty container park or container terminal, the COS is the heartbeat of your scalable operation, driving the cost, productivity and environmental savings for you.

How big is the COS?

The COS dimensions are approximately 19m x 19m x 7m. Given the COS is collapsing 40’ HC COLLPSECONs into COLLAPSECON Bundles of 4 containers, the COS needs to be this size. The footprint contains all the innovative technology, automation and safety systems required to give COS the necessary speed and scale.

Can I move the COS if I need to?

Yes – the COS is mobile and can be deployed and redeployed. The COS is modular and designed to packed into four 40’ HC COLLAPSECON containers, enabling it to be moved locally, regionally or internationally as the needs of your business change.

What are the safety features of the COS?

COS is designed with 100% safety in mind. The operator is stationed at a safe working distance from the fully automated operation in a dedicated control room. Added to that, the COS will automatically cut power and stop should it detect any persons inside the system through an array of inbuilt sensors.

I see the potential, but there is too much uncertainty in my current operations. Why should I invest without knowing how the future will evolve?

Naturally, there is a fear of change, and that’s understandable, but growth in global trade demand is set to continue, with Drewry forecasting growth of 6% YoY through until 2025. This growth requires substantial investment in new vessel capacity and new and replacement equipment, all while the industry faces the extreme challenges of decarbonisation and a congested supply chain. Evolution needs to occur. Moving to adopt new technologies can be risky, so with Spectainer, you don’t have to make a capital investment. We work on leasing arrangements, with any leasing costs far outweighed by the compelling savings achieved in all stages of the shipping process.

Industries

Empowering the entire supply chain

The fully automated Spectainer solution can optimise any network at speed. It is easily adaptable on any scale across the door-to-door spectrum, from single customers to specific trade lanes, geographic areas, or on a global basis.

It is Simple, Efficient, Affordable and Safe, and can be operated seamlessly within existing logistics operations for shipping companies, road operators, rail providers, and barge operator of large BCO/IFF.

Shipping lines

Significantly improve operational efficiency while reducing container operating expenses by up to 40%.

Shippers and Consignees

Transparent, cost-efficient solutions to maintain visibility across the entire supply chain and reduce carbon footprints.

Infrastructure & Ports

Expand service streams, increase container throughput and productivity while reducing land footprint.