Job Category: Product Developmnet

Location: Central Area, Singapore

Job Type: Full-time

Job Title: Lead Engineer – COS

Position: Manager

Role Purpose

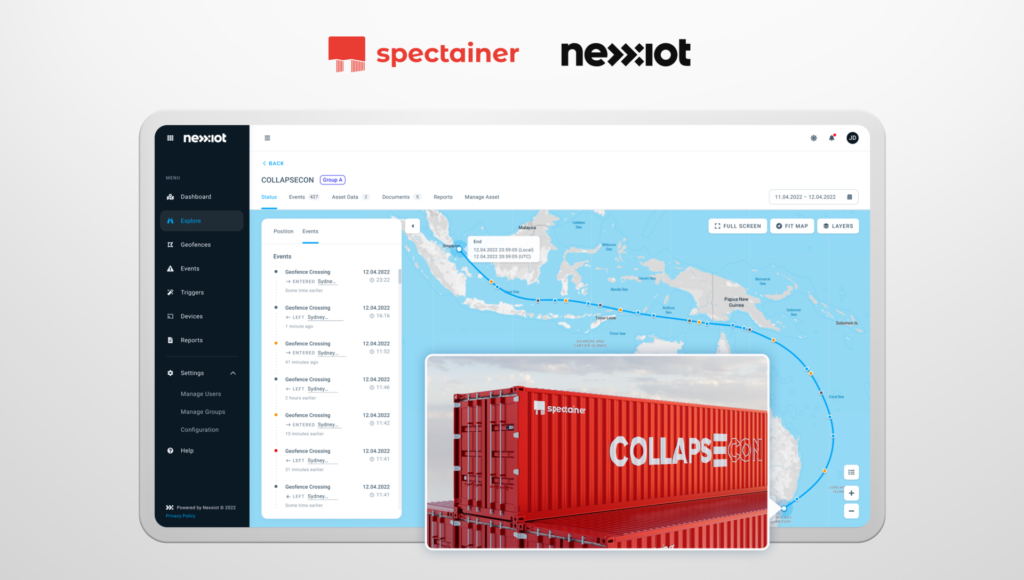

The Spectainer Product Development Team is looking for a lead engineer for our COLLAPSECON Operating Station (COS). The COS is the first automated machine of its kind in the world and the role will primarily be responsible for understanding the challenges unique to executing the design for this system. The ideal candidate has experience in designing automated systems in an industrial scale, thinks creatively to find solutions when problems and delays arise and communicates clearly. Proven experience in industrial size machinery and systems, PLC, automated crane systems and similar areas are required.

The successful Lead Engineer – COS will prioritise simple, first-principles solutions to design, efficiency, and quality challenges as they emerge.

Reporting to: Head of Product Development

Location: Singapore

Duties will include:

- Lead Spectainer’s COS design improvement; collaborate with product engineer and execution teams to deliver product requirements.

- Ensure updated documentation; Generate 3D, 2D mechanical design and Bill of Material (BOM) accurately.

- Troubleshoot and diagnose machine issues, deploy necessary modifications to design.

- Lead the vendors/suppliers in the component selection process.

- Clearly define electrical, software requirements and parts specification to suppliers.

- Maximise resources and track progress through weekly reports on project status including cost, labour and timeline issues.

- Document the entire assembly process for COS.

- Provide direction and guidance to junior peers.

- Collaborate with Product Lead – COLLAPSECON to ensure that the COS is updated to operate the latest COLLAPSECON design.

- Draft technical documentation including manufacturing and quality assurance, drawings assemblies and components in addition to other clerical and document control activities.

- Use CREO to create 3D models and drawings, if needed.

- Perform design verification and validation testing from start to finish.

- Planning, developing, and carrying out experimental test programs to ensure designs meet final product specifications.

Key Skills and Qualifications:

- A Bachelor’s Degree in Mechanical engineering with a focus on automation and mechatronics.

- Proven hands-on experience in managing industrial automation projects from concept to finish.

- First-hand experience with developing processes and methodologies in industrial environments.

- Knowledge of Creo Parametrics.

- Knowledge in MS Office.

- Proficient in English and Mandarin.

- Demonstrated interest in working at the intersection of product design, manufacturing and engineering.

Compensation and benefits:

- Fixed Annual Salary: $75,000-$85,000

- Overtime Grab food & ride allocation

- Generous 20 days annual leave allocation

- Employee Medical Insurance

- Staff pantry stocked with snacks and beverage

- In-house coffee from Homeground Coffee

- Close to public transport and multiple car park options available

- Ergonomic workstations for each team member

- Collaborative office layout

- Shower facilities

Pay offered may vary depending on multiple factors, including job-related knowledge, skills, and experience. The total compensation package for this position may also include other elements dependent on the position offered.

Spectainer is an Equal Opportunity employer. All qualified applicants will receive consideration for employment.