COLLAPSECON

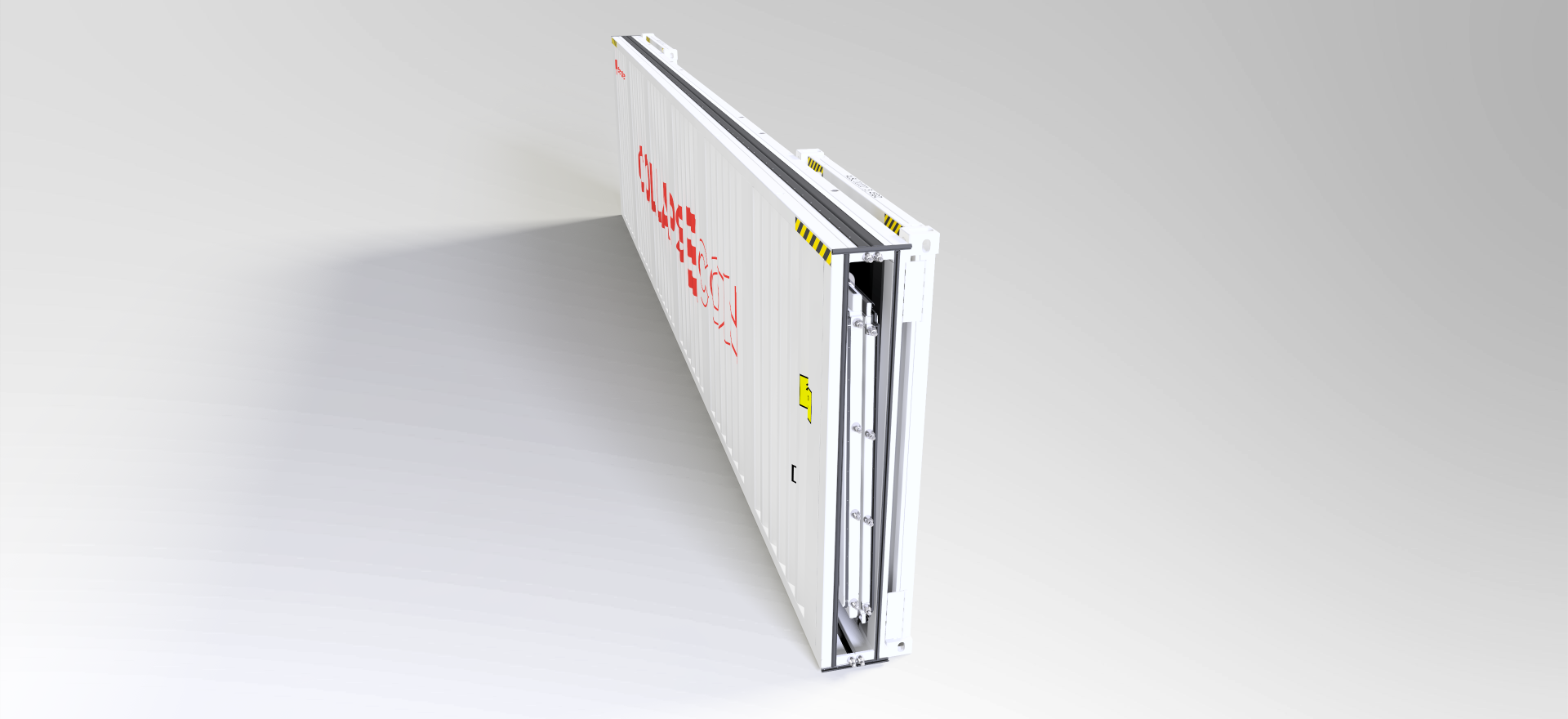

COLLAPSECON is the next evolution of shipping containers – a fully automated collapsible container that will improve operational efficiencies, deliver economic savings and reduce environmental impact across the supply chain, all without requiring a fundamental change to the industry or global trade.

Key Features

Introducing COLLAPSECON

COLLAPSECON is the collapsible shipping container pioneering the future of global trade. It’s practical and rigid design saves on space, cost and handling, and helps to significantly reduce industry emissions.

What makes COLLAPSECON different?

COLLAPSECON containers are collapsed at speed by the COLLAPSECON Operating Station, the only automated solution on the market. It is designed to seamlessly integrate into operations at scale, without requiring wholesale change. It comes with 100% fleet management of maintenance and repair.

| Specifications | ||

| External Dimensions | COLLAPSECON 40’ HC | CONVENTIONAL 40’ HC |

| Length | 12,186 mm | 12,192 mm |

| Width | 2,436 mm | 2,438 mm |

| Height | 2,894 mm | 2,896 mm |

|

Internal Dimensions |

||

| Length | 11,988 mm | 12,036 mm |

| Width | 2,348 mm | 2,352 mm |

| Height | 2,735 mm | 2,698 mm |

| Tare Weight | 6,865 kgs | 4,257 kgs |

| Tare Weight of a ‘COLLAPSECON Block’* | 27,460 kgs | N/A |

| Payload Capacity | 25,635 kgs | 28,243 kgs |

| Gross Weight | 32,500 kgs | 32,500 kgs |

| Cubic Capacity | 77.0 m3 | 76.31 m3 |

|

Door Opening Dimensions |

||

| Width | 2,232 mm | 2,340 mm |

| Height | 2,594 mm | 2,585 mm |

| *4 x COLLAPSECON’s combined into a COLLAPSECON Block for shipment. | ||

|

|

4.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40% Reduction In Container Operating Expenses

Benefits across the entire supply chain, from economic savings, to increasing operational efficiencies and less environmental impact.

75% Reduction In Empty Container Handling Costs

Economic savings through reduced empty park, lifts, storage, transport, and handling costs while increasing conventional container throughput.

37% Reduction In Carbon Emission On Land

Carbon emission reduction on land of up to 37% through less trucking and rail activity between Empty Container Parks and Container Terminals.

17% Further Reduction In Carbon Emissions

Improved vessels’ stowage efficiency on heavily imbalanced trade routes, contributing to a further ~17% in carbon emission.

4x Increased Operational Speed & Handling

4 times the empty containers can be repositioned in the same time it takes to reposition 1 standard container, with minimal change to the operations.

27% Reduction In Daily Fuel Consumption

~12% reduction in at-sea speed (slow steaming) equals an average reduction of 27% in daily fuel consumption and fewer greenhouse-gas emissions.

Frequently Asked Questions

Collapsible containers are not new. What makes this different to anything that has come before?

It’s true, the concept of collapsible containers is not new. The idea has been around since at least the late 1980s, and there have been a number of collapsing containers introduced to the global shipping industry; but each of them has inherent limitations in that they require extensive manual intervention which introduces significant health and safety risks into traditionally highly mechanised handling procedures. COLLAPSECON is completely original in design. While most collapsible designs fold vertically, Spectainer recognised a number of problems associated with the “falling roof” design and developed a horizontally collapsing container to work in tandem with our very own COS for automated operation, thus removing manual operators from the risk zone and significantly improving the efficiency in collapsing and combining containers.

What makes COLLAPSECON different from other collapsible containers?

Many collapsible containers require 3-4 people and a crane to operate, often taking 15-20 minutes per unit to collapse, usually by lifting or pushing the container. This causes increased wear and tear, slows operations and increases safety risks. By comparison, COLLAPSECON has true stand-back functionality. It is fully automated and can be collapsed using the COS in two minutes.

Why collapse horizontally?

Collapsing vertically has its benefits, but strength is not one of them. Given the requirement to position containers anywhere on a vessel, the industry must be confident that a collapsible container can sustain the weight of fully laden boxes both at sea and in the port. Vertically collapsing designs have always had limitations as to their stacking capacity. As COLLAPSECON collapses horizontally and utilises strong integrated end-frames, it can sustain 378T and be positioned anywhere on a vessel (even at the bottom of the stack) in either the single or combined state.

How does COLLAPSECON collapse and combine?

While many designs have achieved the core function of collapsing, an ongoing limitation has been that they are still treated as individual units. This means they save in storage and transport but are still required to be handled individually. To ensure the system is simple, efficient, affordable and safe, COLLAPSECON is designed to be collapsed/expanded using the COS. Most importantly, every container is only touched once in the process, thereby reducing the overall handling requirement. Additionally, each unit combines using the end frames which means there are no external parts. When combined, four units can be treated as a single unit.

What sort of standards are used?

COLLAPSECON must perform like any other standard intermodal container. It is made in the same factories, from the same materials, utilising the same processes. It is designed and certified to the same CSC and ISO standards as a normal container and production requires the same level of rigorous testing. Whether in the single or combined state, rest assured the container acts like a standard container.

I see the potential, but there is too much uncertainty in my current operations. Why should I adopt this sort of technology without knowing how the future will evolve?

Naturally, there is a fear of change, and that’s understandable, but growth in global trade demand is set to continue, with Drewry forecasting growth of 6% YoY through until 2025. This growth requires substantial investment in new vessel capacity and new and replacement equipment, all while the industry faces the extreme challenges of decarbonisation and a congested supply chain. Evolution needs to occur. Moving to adopt new technologies can be risky, so with Spectainer, you don’t have to make a capital investment. We work on leasing arrangements, with any leasing costs far outweighed by the compelling savings achieved in all stages of the shipping process.

Industries

Empowering the entire supply chain

The fully automated Spectainer solution can optimise any network at speed. It is easily adaptable on any scale across the door-to-door spectrum, from single customers to specific trade lanes, geographic areas, or on a global basis.

It is Simple, Efficient, Affordable and Safe, and can be operated seamlessly within existing logistics operations for shipping companies, road operators, rail providers, and barge operator of large BCO/IFF.

Shipping lines

Significantly improve operational efficiency while reducing container operating expenses by up to 40%.

Shippers and Consignees

Transparent, cost-efficient solutions to maintain visibility across the entire supply chain and reduce carbon footprints.

Infrastructure & Ports

Expand service streams, increase container throughput and productivity while reducing land footprint.